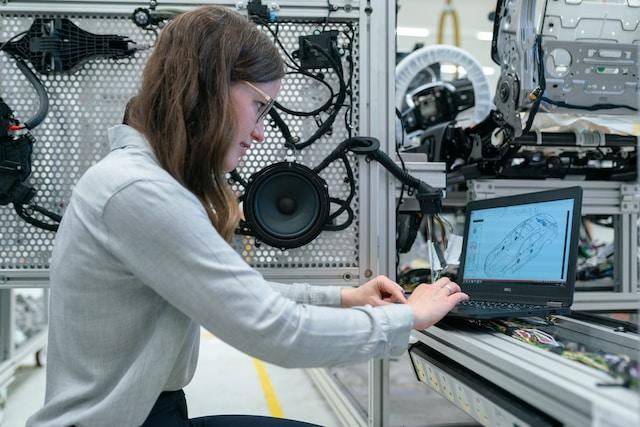

Engineered-to-Order (ETO) companies offer unique solutions for customers who demand customized products. This type of manufacturing requires a high level of engineering and design expertise, as the product is designed and built to meet the exact needs of the customer, instead of making use of previously established templates or models.

These companies often rely on outdated methods of project management and process tracking. With the advancements in cloud technology, there are powerful softwares available like Enterprise Resource Planning systems (ERPs) that can help ETO manufacturers save time, money, and resources by eliminating manual tasks while increasing efficiency with better processes and workflow. In this blog, we will define ETO, discuss how ERP software can improve ETO processes, and introduce you to a highly specialized ERP solution designed with engineers in mind.

What is an ETO Company?

Engineered-to-Order (ETO) is a manufacturing method that allows customers to work with a manufacturing team to make each product unique. The designing process begins after the customer has placed an order. Unlike conventional manufacturing, ETO manufacturing involves highly iterative processes that are design oriented and client-centric. There is a lot of creativity involved as engineers try to convert clients’ concepts into reality through continuous collaboration right from design to delivery.

How Software Can Improve an ETO Company

Many ETO companies are still using spreadsheets and doing all of their project management manually. Integrating software like Enterprise Resource Planning systems (ERPs) eliminates the need for that and allows manufacturers to focus less on the repetitive tasks involved in project management and more on creating the end product. Implementing an ERP can help ETO companies improve by:

Increasing automation & workflow management: ERP software helps to automate processes such as order management, order entry, and product configuration. This automation can help improve efficiency and accuracy in the order fulfillment process.

Reduced production costs: An ERP can help reduce costs associated with production, inventory management, and delivery. By automating processes, companies can reduce labor costs and save time that can be put towards more productive activities.

Improved quality control: ERP software allows for better quality control throughout the manufacturing process. Automated processes ensure that each product is built to a high standard and meets customer requirements.

Improved visibility: One of the better benefits of ERP software is that it provides real-time visibility into the manufacturing process. This helps to identify any issues that may arise and allows for quicker resolution.

Improving customer service: Improving efficiency and productivity by automating repetitive tasks allows manufacturers to fulfill customer orders faster while also reducing costs. Customers are left satisfied that they received high-quality goods in a convenient time frame at a reasonable cost.

Overall, integrating ERP software helps organizations streamline their engineer-to-order processes. It empowers engineers to quickly configure customized products, create detailed product models, and ensure accurate production setup. The system also automates activities such as purchasing decisions, order tracking, and billing cycles, while offering in-depth reporting capabilities to gain insights into the health of a company’s operations.

That all sounds great but, there is a plethora of products available on the market that are designed to be used as ERPs. How do you choose the right one for your business?

COUNTERPART ERP: The Best ETO Software in 2023

COUNTERPART® is a highly specialized ERP solution designed exclusively for engineer-to-order manufacturers and custom-design machine builders in automation, material handling, and original equipment industries. It allows users to share information with those who need it, see real-time progress, and allow businesses to leverage the information to increase efficiencies in engineering, procurement, manufacturing, and more. Some of the benefits of using COUNTERPART® include:

- Sales & estimating, quoting and change orders, and parts orders

COUNTERPART® was designed with engineers in mind so it seamlessly integrates with SOLIDWORKS® to eliminate the need to export BOMs, use spreadsheets, or manually enter data into your ERP. - A unique hold & release system

COUNTERPART® allows engineers the ability to release completed assemblies and long lead items to purchasing early on while holding back incomplete designs until ready. This effectively eliminates bottlenecks in procurement that prevent ETO manufacturers from getting jobs done on time. - Purchasing

This aspect of the software allows for more time to issue RFQs and shop for the best pricing and availability. As designs change, COUNTERPART® reconciles changes to required materials and notifies your buyers so they can cancel or return any unnecessary orders, saving you money. - Inventory management and location tracking

When a project is completed, any leftover inventory can be added and tracked in the inventory management system. The COUNTERPART® system tracks locations by having a list of predefined locations in the settings, including anything from shelves to desired individuals. The locations are customizable and are set up during implementation to be specific to the company in question. The system then tracks where components are routed between locations as their path to being procured, picked, or manufactured is followed. The result is visibility to the users of where the component is located at each step of the process up until it is added to the final product. - Fabrications can be tracked at all stages, both in-house and farmed out.

With Purchasing, Routing, Receiving, and Quality Control in one system, expediting information is readily available so buyers can stay on top of vendors for late deliveries and monitor supplier performance. This gives ETO manufacturers the ability to ensure that they are working with the best vendors to bring their customers quality products within a reasonable price and time frame. - Financial and data analysis

Financial and data analysis is made easy with reports including Real Time Committed Job Costing, allowing users to slice and dice data as needed. Accounts payable and receivable invoices can also be integrated with feature-rich, industry-proven accounting systems such as QuickBooks.

At COUNTERPART®, we want to be the aspirin, not the headache. We have worked to build an ERP solution that eliminates the need for repetitive manual tasks like data entry and provides the best applications for your ETO needs. Schedule a demo today to learn more about what we can do to automate your systems, increase your productivity, and make your life easier.