COUNTERPART Case Study: ARMI

A Journey to Streamlined Communications Between Engineering and Manufacturing

Challenge: A Failed ERP Implementation

ARMI faced a challenge when their initial ERP choice did not fit their needs. Frustrated, they opted to function without an ERP system to track their processes. They lacked an efficient way of managing their engineering workloads, internal manufacturing and assembly, and communication. This resulted in operational inefficiencies and growing lead times.

Solution: Streamline Communications

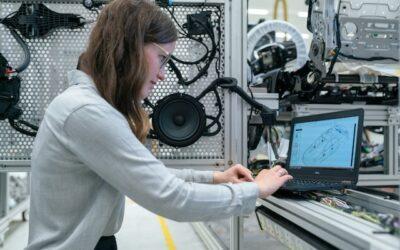

ARMI had an urgent need to fill. COUNTERPART emerged as the ideal solution to streamline their operations. ARMI leveraged COUNTERPART’s innovative capabilities, to bridge the gap between engineering and manufacturing processes.

COUNTERPART’s integration with SOLIDWORKS and PDM allowed them to instantly communicate needs without having to manually gather information and drawings. They focused on transforming their engineering data management and communication. The end goal was to enhance collaboration and data-driven decision-making.

Outcome: Streamlining Success with COUNTERPART

The implementation of COUNTERPART ushered in a transformative era for ARMI. By aligning their engineering and manufacturing workflows, COUNTERPART enabled ARMI to break free from data silos and leverage their existing data for greater efficiency. Their old process of having their engineers manually create build books with drawings and part counts was 100% eliminated. COUNTERPART gave them the ability to fully automate this process. The streamlined process now allows ARMI to transition from engineering to manufacturing seamlessly. It also reduces time-to-market and improves overall operational agility.

The partnership with COUNTERPART propels ARMI toward a new realm of manufacturing distinction. It’s a shining example of how a seamlessly integrated ERP can reshape business processes and results.

Recent Blogs

The Best ETO Software to Integrate in 2023

Engineered-to-Order (ETO) companies offer unique solutions for customers who demand customized products. This type of manufacturing requires a high level of engineering and design expertise, as the product is designed and built to meet the exact needs of the customer,...

Top 13 benefits of an ERP Software for manufacturing companies

Manufacturing businesses are always looking for ways to cut costs, increase efficiency and productivity, and have a better understanding of their market. Enterprise resource planning systems (ERPs) are solutions that encompass supply chain and inventory management,...

The Ultimate Inventory Management Guide for ETO

Proper inventory management is a critical part of any business that manufactures goods. Having too much inventory can take up resources like capital and warehouse storage but too little inventory can lead to longer lead times for customers and lost revenue for the...