COUNTERPART®. Seamless Inventor Integration

Increase Visibility • Collaboration • Efficiency • Profits

COUNTERPART is the right ERP solution for your team

COUNTERPART® provides your team access to all the live information they need to do their jobs better. Through a direct integration with your Autodesk Inventor software, there is no longer a need to export BOMs, use spreadsheets, or manually enter data into your ERP. Share information with those who need it, see real-time progress, and allow your business to leverage the information to increase efficiencies in engineering, procurement, manufacturing and more.

Why choose COUNTERPART?

Implementing an ERP into your company can create a lot of benefits for your team, but the clearest benefits are noticed through the improved workflow and increased amount of visibility.

Increase visibility

COUNTERPART makes it possible to communicate with your entire team through a single app. From engineering to procurement, to assembly and manufacturing. You will have everything you need in one space so that each party has 100% visibility into the project. This removes the probability of errors, and ensures everyone has the most updated BOMs and REVs.

Increase collaboration

With increased transparency, comes increased collaboration. Each party involved in the process from engineering to manufacturing can collaborate within COUNTERPART. From drawing files to BOMs created directly in your CAD software everyone has access to the same data, saving time, and ensuring accurate data.

Increase efficiency

Creating BOMs directly in your Autodesk software removes a lot of duplicated work, and simplifies the overall workload for your entire team. It removes the need for any double entry, messy excel sheets, and lets your engineers stick to engineering projects, not administrative tasks.

Increase profits

With time savings, and increased production levels, the only thing left is profit. COUNTERPART not only improves your organizational workflow, but it also tracks and helps to perfect inventory management to make sure that you have the right parts, at the right times, and are remaining efficient.

COUNTERPART ERP Solutions

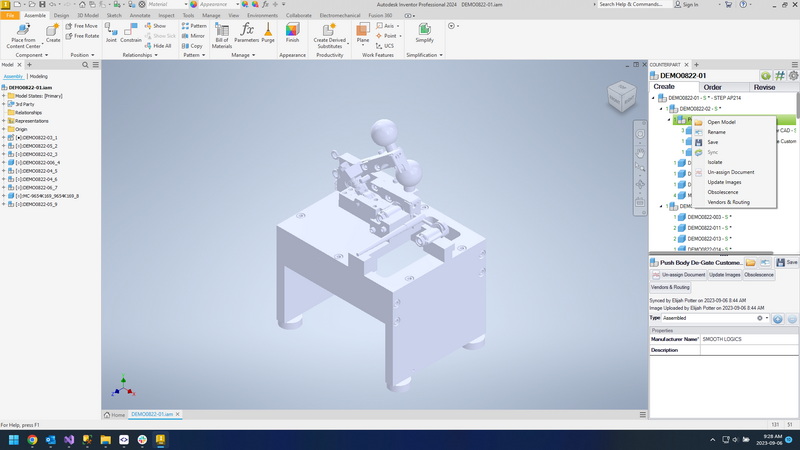

Engineering

Seamless Autodesk Inventor software integration makes COUNTERPART a perfect fit for engineering teams. Improving communication, workflows, and creating complete and accurate BOMs directly in your existing software package keeps the engineers focused on the work they are hired to do.

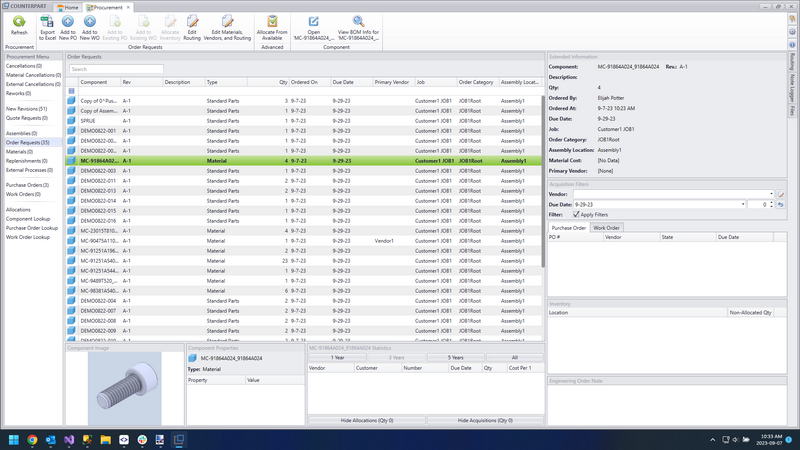

Procurement

Increase project efficiency by eliminating the need for reports to know what comes next while automatically prioritizing the next actions. The integration will also improve the speed and efficiency of issuing POs through the Vault integration. You can reduce the number and frequency of POs that each project requires by allowing multiple jobs on a single PO, and still seamlessly tracking the costing and picking/kitting of all items on that single order.

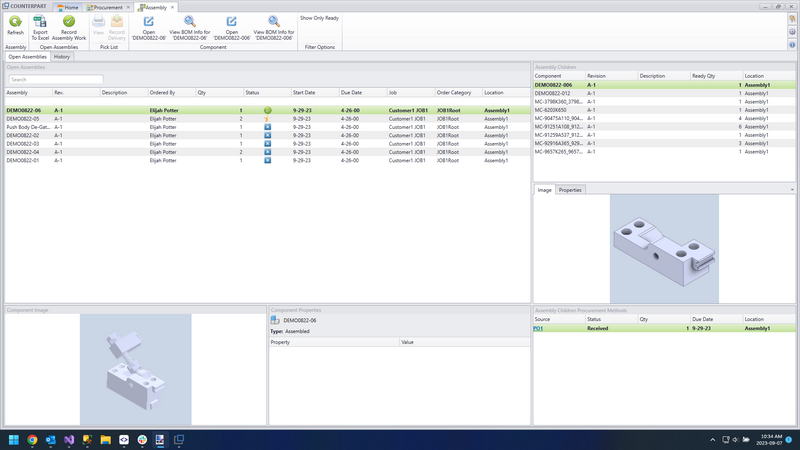

Assembly & Manufacturing

COUNTERPART gives you the ability to manage your workflows, and optimize priority for assembly. You will get visibility of all parts and their status, with instant access to drawings/models. This allows you to know what is ready, when it’s ready, and provides an overall improvement in project visibility.

Here’s what our customers are saying

Recent Blogs and Case Studies

How Custom Engineering and Manufacturing ERP Software Enhances Productivity and Efficiency

You’ve probably heard the term Enterprise Resource Planning (ERP) software before. If not, or as a refresher, they are a powerful application companies use to streamline and manage daily tasks across different departments. ERPs are used in nearly every industry from...

8 Reasons an Engineering ERP Makes Manufacturing Better

As an Engineer, you do a lot of clicking – mouse clicks to be specific. You do it in your design software, you do it to open and close other applications like spreadsheets and project management software. And you spend a lot of time clicking fields and...

Solving Challenges to the Manufacturing Process with a SOLIDWORKS ERP

Let’s consider a hard question: Are you really in charge of your manufacturing business or are the systems you depend on controlling you? You know the answer if you and your people are spending far too much time flipping back and forth between different software...