COUNTERPART Case Studies

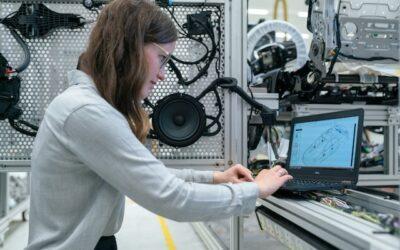

ARMI

When their initial ERP choice didn’t meet their needs, ARMI chose to work without one. Once they realized they needed a new ERP partner, they found COUNTERPART. Read about their journey to streamlined communications between engineering and manufacturing.

Sebright Products

Sebright selected COUNTERPART as their ERP solution to help control costs and create scalable processes. Read how they achieved their smoothest implementation ever with the highest return on investment – increasing EBITDA by 45% after the first year.

Jerit Automation

Jerit had to produce machines and while they were similar to each other, each one had a distinct requirement that made it unique. They turned to COUNTERPART to help them streamline their workflows and enhance precision.

Recent Blogs

The Best ETO Software to Integrate in 2023

Engineered-to-Order (ETO) companies offer unique solutions for customers who demand customized products. This type of manufacturing requires a high level of engineering and design expertise, as the product is designed and built to meet the exact needs of the customer,...

Top 13 benefits of an ERP Software for manufacturing companies

Manufacturing businesses are always looking for ways to cut costs, increase efficiency and productivity, and have a better understanding of their market. Enterprise resource planning systems (ERPs) are solutions that encompass supply chain and inventory management,...

The Ultimate Inventory Management Guide for ETO

Proper inventory management is a critical part of any business that manufactures goods. Having too much inventory can take up resources like capital and warehouse storage but too little inventory can lead to longer lead times for customers and lost revenue for the...