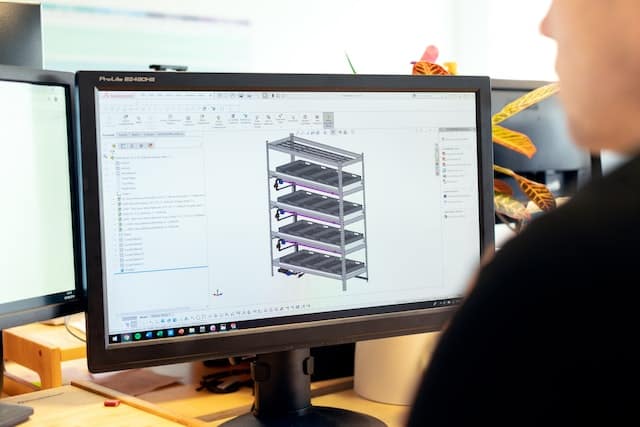

Jerit Automation faced a unique challenge in its manufacturing process. They were producing many similar machines but each project had distinct requirements that made them unique. The differences led to time-consuming manual processes and extensive double-checking. After all, they needed to ensure precision before the project reached the production floor.

Knowing that they had intricate manufacturing demands, they set out to look for a solution. A strategy centered around streamlined workflows was proposed. The goal was to integrate a solution capable of harmonizing diverse project specifications. Enter COUNTERPART to aid in reducing manual efforts and minimizing the potential for errors.

Knowing that they had intricate manufacturing demands, they set out to look for a solution. A strategy centered around streamlined workflows was proposed. The goal was to integrate a solution capable of harmonizing diverse project specifications. Enter COUNTERPART to aid in reducing manual efforts and minimizing the potential for errors.

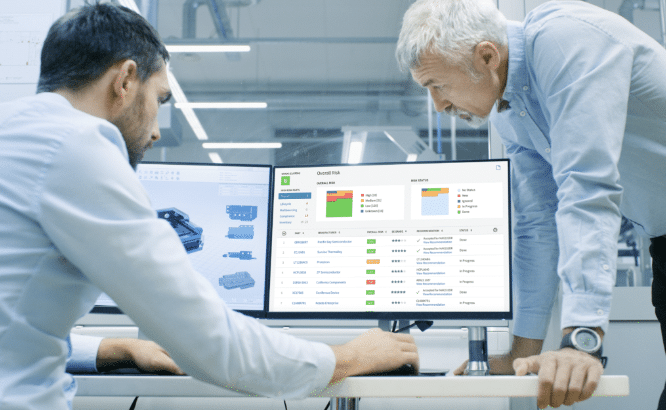

The successful implementation of COUNTERPART workflows has yielded remarkable results for Jerit Automation. By embracing a more efficient approach, they eliminated the excessive manual workload and exhaustive double-checking. As the initial challenges were effectively resolved, a new chapter has begun. With the initial hurdles out of the way, Jerit Automation is now empowered to tackle any new issues with agility and resourcefulness.

The successful implementation of COUNTERPART workflows has yielded remarkable results for Jerit Automation. By embracing a more efficient approach, they eliminated the excessive manual workload and exhaustive double-checking. As the initial challenges were effectively resolved, a new chapter has begun. With the initial hurdles out of the way, Jerit Automation is now empowered to tackle any new issues with agility and resourcefulness.

This transformation highlights the potential of well-tailored solutions in reshaping manufacturing processes. Jerit Automation’s journey underscores the power of technology. It is an example of how the right ERP solution, like COUNTERPART, can reshape efficiency, drive progress, and equip businesses to confidently address new challenges.

© 2025 Smooth Logics, LLC

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.