Custom manufacturing is complex. Every customer has new requirements, and every order demands new engineering work. That uniqueness sets Engineer-to-Order (ETO) manufacturers apart, but it also creates long lead times, constant changes, and miscommunication between teams.

Generic ERP software doesn’t work well work for ETO businesses because it doesn’t align to an engineering-led manufacturing process, it doesn’t connect to CAD, and it forces the shop to adapt to workflows that don’t fit.

An Engineer-to-Order ERP helps integrate your engineering data with purchasing, inventory, manufacturing, and finance so every department works together on live, accurate information. This guide explains how ETP ERPs work and how they help custom manufacturers grow.

What is an Engineer-to-Order ERP

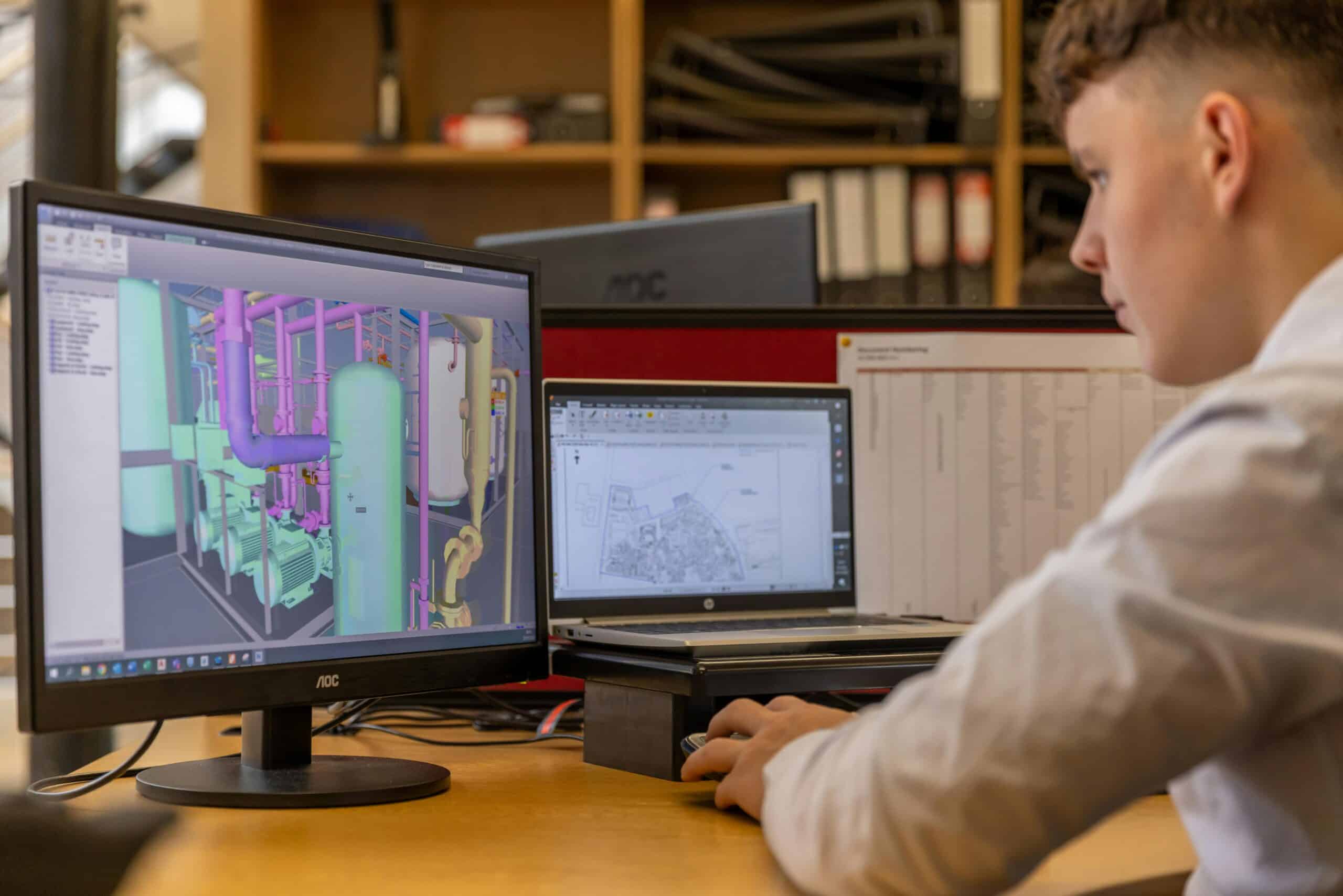

An Engineer-to-Order ERP software is designed specifically for ETO workflows. It does everything a standard ERP does, like tracking inventory, scheduling production, managing costs, and consolidating project data. But, more importantly, it connects those functions to an engineering-first approach that’s highly adaptable and integrated with your CAD.

With the right ETO ERP you can generate BOMs directly from CAD, update them instantly when a design changes, track project profitability in real time, and give every department live visibility into progress.

Why the Engineer-to-Order Process Is Difficult to Manage

ETO businesses often struggle to scale because of long lead times and inefficient workflows. At each stage of the ETO process, bottlenecks appear.

In engineering, BOMs are built manually and re-entered by hand into the ERP, which often results in errors and delays. In procurement, buyers discover too late that BOMs have changed, so they backtrack on orders or scramble to source alternatives. On shop floors, teams find themselves building from outdated versions of the design. In finance, project profitability is unclear until weeks or months later when mistakes can no longer be corrected.

The result is slow, unpredictable growth. You can deliver quality work for customers, but you cannot increase capacity without adding more headcount for manual tasks.

Why Generic ERP Systems Fail ETO Manufacturers

Most ERP systems are built for mass production (i.e., make-to-stock manufacturing). They assume stable BOMs, repeatable workflows, and predictable scheduling. That does not reflect the ETO reality.

Generic ERP systems fail ETO companies for specific reasons:

- They ignore engineering, since they are designed mainly for finance and operations.

- They do not integrate with CAD programs, so BOMs require endless manual updates.

- They create data silos instead of unifying downstream departments from engineering.

How an Engineer-to-Order ERP Solves These Challenges

- For engineering, an ETO ERP integrates directly with CAD so BOMs are created once instead of re-entered multiple times. When designs change, BOMs update instantly for everyone. Engineers spend less time on administration and more time designing.

- For manufacturing, it ensures the BOM on the shop floor matches CAD. Assemblies and components are tracked in real time. Notifications show when statuses change and which jobs to prioritize first.

- For procurement, it cuts paperwork and creates clarity. Accurate BOMs reveal required material demand for each job. Buyers issue fewer purchase orders while still keeping projects supplied. They can also measure vendor performance and avoid bottlenecks.

- For finance and management, job costing and profitability are tracked in real time. Instead of waiting months for financial clarity, leaders make proactive decisions based on live data.

Together these improvements reduce lead times, minimize errors, speed up collaboration, and increase capacity.

Best Practices for Using an ERP in the Engineer-to-Order Process

To make the most of ERP in an ETO environment, follow best practices that reinforce efficiency:

- First, BOM management should be dynamic, not static.

- Second, release long-lead items early with a system like COUNTERPART so procurement starts work while engineering continues refining designs.

- Third, prioritize transparency. Use ERP data to show real-time progress so all teams stay aligned.

- Finally, review supplier performance and vendor data regularly to prevent repeated bottlenecks.

COUNTERPART ERP: Engineer-to-Order Made Simple

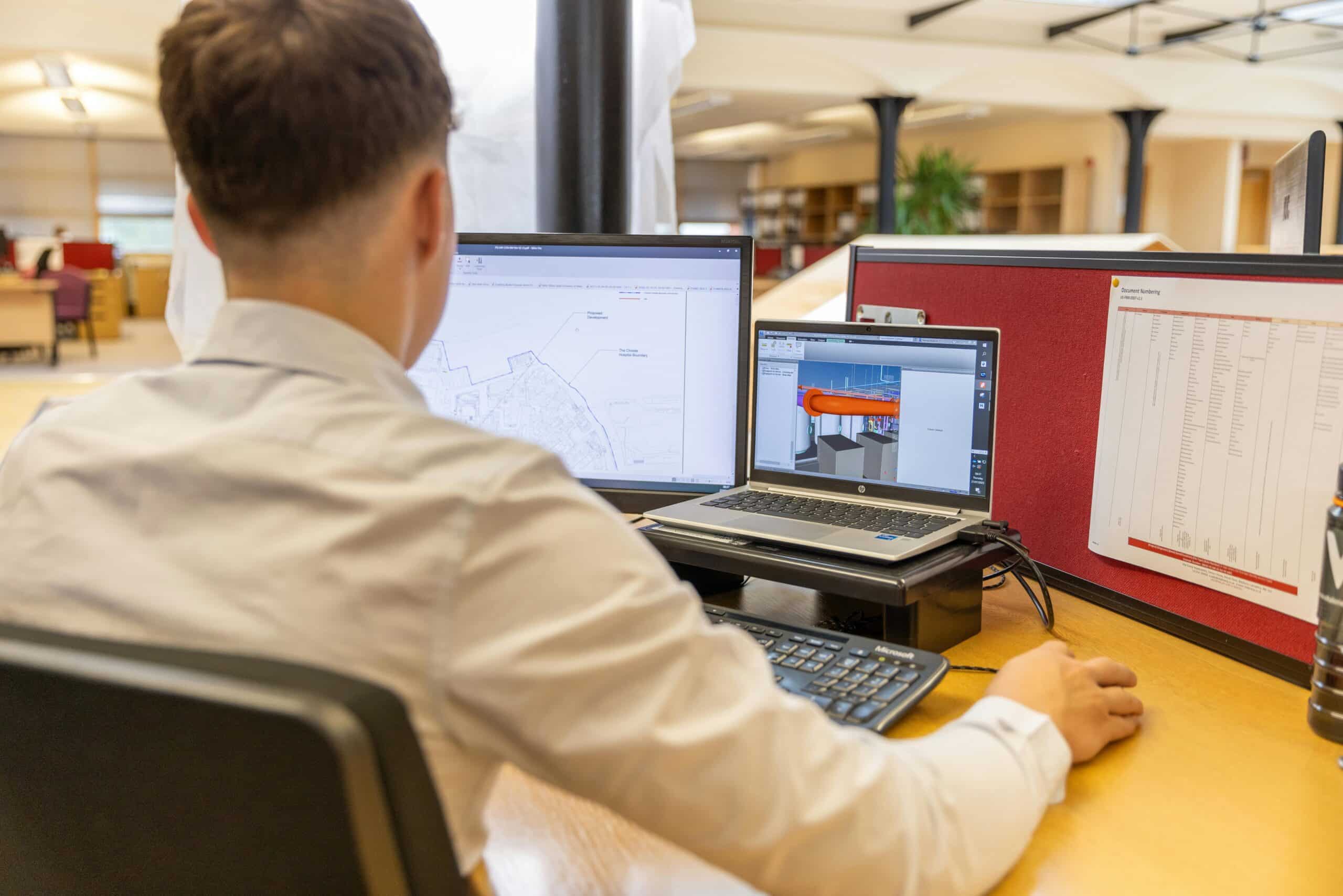

COUNTERPART ERP was developed by engineers who wanted ERP that worked in engineering as well as manufacturing and accounting.

It integrates directly with SOLIDWORKS and Autodesk Inventor. BOMs are created inside CAD and update instantly whenever designs change. Long-lead items release early to purchasing while incomplete designs remain on hold until ready. Buyers are notified of changes as they happen. Assemblies and components are tracked through inventory, procurement, and production with live visibility.

COUNTERPART ERP delivers configurability without heavy, expensive customization and gives real-time project costing at every level. It is designed for engineer-led manufacturers that want efficiency, accuracy, and control.

FAQs on Engineer-to-Order ERP

What is an Engineer-to-Order ERP?

It is ERP software built for ETO manufacturers. It connects CAD and engineering workflows to procurement, manufacturing, and finance.

How is an Engineer-to-Order ERP different from a generic ERP?

It supports custom BOMs, integrates directly with engineering design tools, and allows workflows to adapt to how manufacturers actually work.

Why are lead times long in Engineer-to-Order manufacturing?

Each job involves a new design, new BOMs, and custom procurement, which slows down the process.

How does an ERP reduce lead times in ETO?

By automating BOM management, centralizing data, and giving every department real-time visibility, ERP eliminates manual backlogs and delays.

Does an Engineer-to-Order ERP work for small manufacturers?

Yes. Smaller teams benefit because they save time on repetitive administration and avoid costly duplication of effort.

Scale Faster by Streamlining Your Engineer-to-Order ERP Process

ETO is complex. Generic ERP systems don’t fit. Engineer-to-order ERP connects CAD, engineering, procurement, manufacturing, and finance into one system, reducing lead times and giving manufacturers capacity to grow. If you want to shorten lead times and scale without adding overhead, schedule a COUNTERPART demo today.