In Engineer-to-Order (ETO) manufacturing, every job begins with unique customer requirements. Every Bill of Materials is also subject to change throughout the design and delivery process, plus procurement and manufacturing are constantly adapting as engineering refines the design. That’s why the Engineer-to-Order process is both rewarding and challenging: you deliver exactly what the customer needs, but it’s hard to build scalable processes.

Enterprise Resource Planning (ERP) software purpose-built for ETO can help fix these scalability and efficiency issues. With an ERP that’s tightly integrated to CAD and all downstream operations, you gain visibility, accuracy, and collaboration that cuts wasted time and removes bottlenecks.

This article breaks down the Engineer-to-Order process, the challenges that slow it down, and how the right ERP can help you optimize each step.

What is the Engineer-to-Order Process

Engineer‑to‑Order (ETO) manufacturing is a production model where a company designs, engineers, and builds a product only after a customer places an order. Each project begins with unique requirements that often have never been built before, because the customer’s needs are specific to their application or environment. In ETO, the design phase drives the entire process—engineering, procurement, and manufacturing all collaborate to develop a custom solution rather than relying on pre‑existing products or templates.

This method is common in industries such as industrial machinery, automation and robotics, aerospace, material handling, and custom equipment manufacturing, where complex specifications and tailored performance standards make every project distinct..

A typical ETO process follows these stages:

- Capture customer requirements.

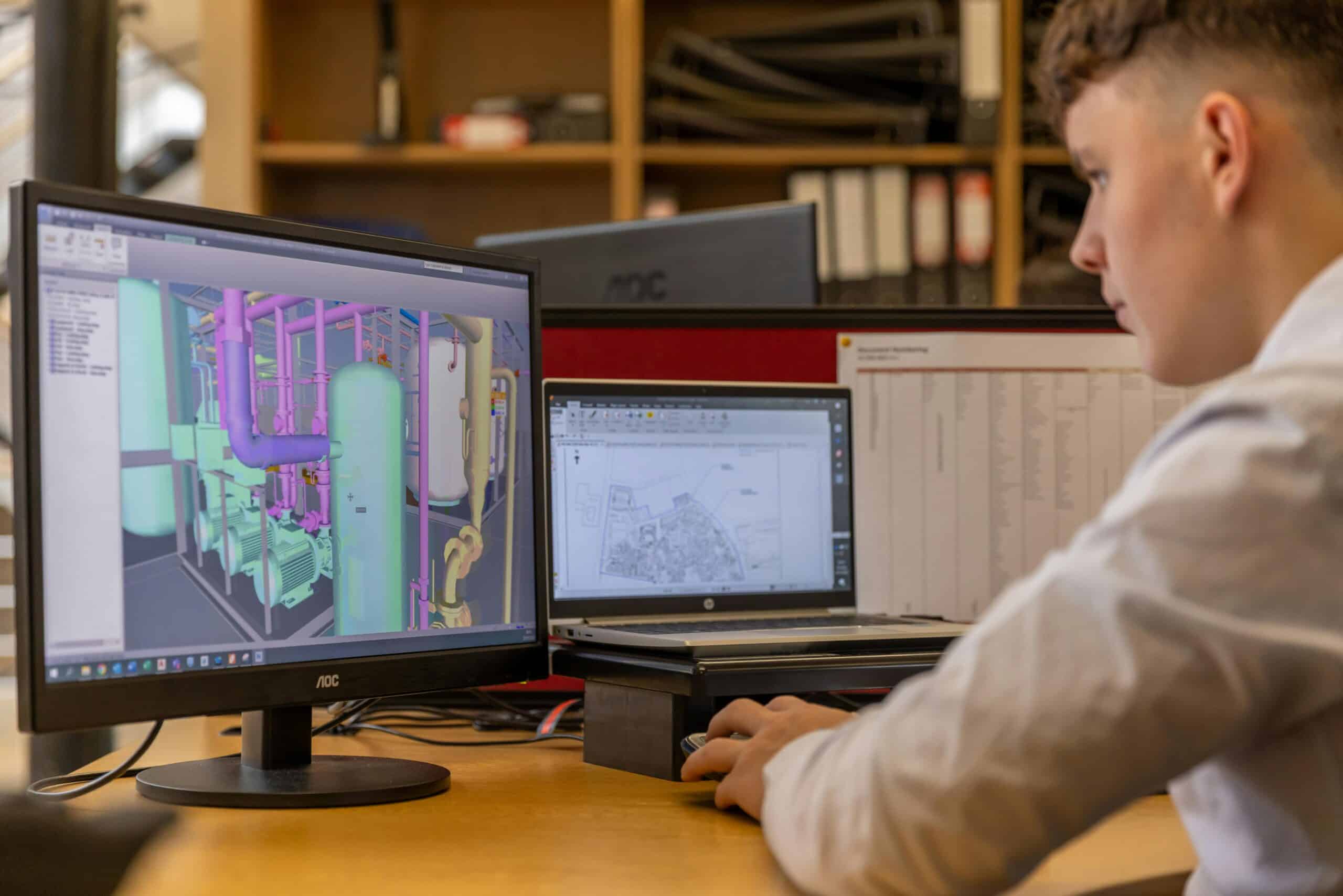

- Engineering creates a design in a CAD program like SOLIDWORKS or INVENTOR.

- A Bill of Materials (BOM) is generated and revised.

- Procurement secures required parts and materials.

- Manufacturing builds assemblies and final products.

- Delivery and customer approval close out the project.

Because each step relies on custom engineering, any inefficiency or miscommunication creates slower lead times, higher costs, and frustrated teams.

Common Challenges in the Engineer-to-Order Process

ETO businesses often want to accept more orders to drive growth, but they struggle with bottlenecks in this lengthy and highly-dependent process. Some of the biggest process barriers to growth include:

- Manual BOM management as engineers export and re-enter BOMs into spreadsheets or ERP, wasting hours and introducing errors.

- Inventory blind spots when purchasing doesn’t know what’s on hand and what needs ordering until it’s too late.

- Department silos due to engineering, procurement, and manufacturing operating in different systems, creating a constant game of catch-up.

- Reactive problem-solving when issues aren’t spotted until they cause delays, leading to last-minute crises instead of proactive planning.

- Vendor variability because, without consistent data on supplier performance, recurring bottlenecks slow down projects.

How an ERP Improves the Engineer-to-Order Process

An Engineer-to-Order ERP addresses these challenges by unifying engineering and manufacturing operations together in one platform that aligns workflows around updated design data.

Inventory insights

An ERP like COUNTERPART can use up-do-date design and inventory data to show what’s already in stock and what needs to be ordered. Buyers can act early, troubleshoot shortages, and align lead times with project schedules.

High-level process visibility

ETO ERP systems create a real-time roadmap where management and teams can see specific workflows, dependencies, and progress markers. This helps prevent upcoming bottlenecks and lets teams work backwards from issues to improve future jobs.

Cross-department collaboration

When your ERP connects CAD data with procurement and shop floor systems, every team works from the same dataset. No manual re-entry. No email chains. Everyone speaks the same language.

Department-Level Benefits of an ERP in ETO Workflows

Engineering

The right ERP (like COUNTERPART) eliminates double data entry by pulling BOMs directly from CAD. Engineers always know the live status of their project so they can prioritize design work instead of busywork.

Manufacturing

An ERP built for ETO manufacturing ensures the BOM in production is the same as the one in CAD. Assemblies and components are visible in real time, so shop floor teams know what can be built now and what needs to wait.

Procurement

An ERP can help automate purchasing needs directly from BOM data. Procurement receive updates as designs change, reducing wasted POs and improving supplier management with real-time data.

Best Practices for Optimizing the Engineer-to-Order Process

- Use an ERP that integrates with your CAD and updates BOMs instantly when designs change.

- Up-to-date data can help you release long-lead parts while continuing design work on hold items.

- Track supplier lead times and reliability to prevent repeated problems.

- Use ERP dashboards to spot issues before they become bottlenecks.

COUNTERPART ERP Streamlines Your Engineer-to-Order Process

COUNTERPART ERP connects engineering and operations so the engineer-to-order process works more smoothly. Built by engineers, it integrates directly with SOLIDWORKS and Autodesk Inventor to create BOMs inside CAD and update them as designs evolve with shifting customer requirements. With real-time project visibility, partial release functionality for long-lead items, live inventory tracking, and job costing down to every part, COUNTERPART ERP gives you the ability to reduce lead times and scale capacity without adding overhead.

Learn more about how COUNTERPART ERP streamlines the engineer-to-order process: schedule a demo today.